How to start an Ethanol Production Plant in India

The world is at a crossroads, grappling with the consequences of excessive reliance on fossil fuels, and India is no exception. Climate change, pollution, and environmental degradation have prompted governments worldwide to seek sustainable and eco-friendly alternatives to traditional fuels. In this context, ethanol, a biofuel produced from renewable sources, has emerged as a promising solution. This comprehensive guide aims to demystify the process of starting an ethanol production plant in India, all while highlighting the pivotal role of the government’s new policies in boosting this vital industry.

Understanding Ethanol: A Cleaner, Greener Fuel

Ethanol, also known as ethyl alcohol, is a colorless and odorless liquid with a wide range of applications. What makes ethanol particularly attractive is its versatility as a biofuel, as it can be derived from various renewable sources, including sugarcane, corn, grains, and even waste materials. However, its most significant contribution lies in the realm of transportation fuels, where it can be blended with petrol.

The Government’s Vision: A 20% Ethanol Blend by 2025

The Indian government has set forth an ambitious target: to achieve a 20% ethanol blend in petrol by the year 2025. Currently, India blends approximately 10% ethanol with petrol, and this mandate represents a significant leap forward in the country’s efforts to reduce pollution, promote environmental safety, and safeguard the health of its citizens.

A Vital Step Toward Pollution Reduction

The quest for cleaner air and a healthier environment is a universal concern, and India is no exception. The subcontinent has witnessed a surge in pollution levels, leading to an alarming increase in respiratory diseases, including asthma. Tragically, this pollution-related health crisis has contributed to a high mortality rate, particularly among the elderly population. Starting an ethanol production plant is a crucial step toward mitigating these environmental and health challenges. By reducing harmful emissions from vehicles, ethanol can substantially improve air quality and public health.

Essential Infrastructure and Machinery for Ethanol Production

Establishing an ethanol production unit necessitates careful planning and investment in infrastructure and machinery. The core components required for a successful ethanol production plant include:

- Grain Storage and Cleaning Plant: A facility for storing and cleaning grains, a primary source of ethanol production.

- Grain Grading and Milling Plant: This unit is responsible for grading and milling the grains, preparing them for the subsequent stages of production.

- Liquefaction Plant: In this plant, the liquefaction process converts starches in grains into fermentable sugars.

- Fermenting Unit: Fermentation is a crucial step where microorganisms, typically yeast, convert sugars into ethanol and carbon dioxide.

- Distillation Plant: Distillation separates ethanol from the fermented mixture, ensuring purity and quality.

- Spent Titration Plant (Spent Wash Evaporator): This section manages the byproduct of ethanol production, ensuring proper disposal or utilization.

- Cooling System: Essential for maintaining optimal temperatures during various stages of production.

Additionally, other infrastructures such as steam boilers and effluent treatment plants are required to support the ethanol production process.

Key Raw Materials for Ethanol Manufacturing

Ethanol production relies on a steady supply of raw materials, primarily:

- C Heavy Molasses: Yields approximately 250 to 275 liters of rectified spirit per ton.

- B Heavy Molasses: Produces roughly 300 to 325 liters of rectified spirit per ton.

- Sugarcane Juice: Provides around 70 to 80 liters of rectified spirit per ton.

- Cereals: Yields approximately 300 liters of rectified spirit per ton.

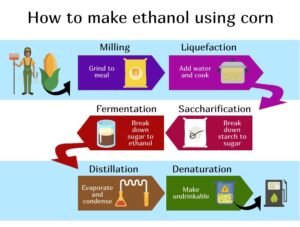

The Ethanol Production Process

The process of ethanol production involves two critical stages: fermentation and distillation.

Fermentation: Initially, Molasses is fermented, followed by the addition of water and yeast. The mixture is left to ferment for 24 hours.

Distillation: The fermented mixture is subjected to distillation, which involves passing it through a sludge remover to separate impurities. The clear material is then heated, leading to the vaporization of alcohol, which is collected for further processing.

Water Treatment Plant: Ensuring access to clean water is vital for the production of high-quality ethanol.

Key Sections of an Ethanol Plant

An ethanol production plant comprises several sections, each playing a unique role in the overall process:

- Distillation Section: This is where the separation of ethanol from the fermented mixture occurs, resulting in purified ethanol.

- Fermentation Section: The heart of the ethanol production process, where sugars are converted into alcohol through fermentation.

- Boiler Section: Responsible for generating steam, a vital component in various stages of production.

- Turbine Section: This section may include turbines for power generation, making the plant more energy-efficient.

- Raw Material Storage Section: A designated area for storing raw materials, ensuring a continuous supply.

- Finished Product Storage Section: This section stores the final ethanol product, ready for distribution.

Government Support: A Catalyst for Ethanol Production

The Indian government has taken significant steps to incentivize and promote ethanol production. These measures include:

- Minimum Ethanol Pricing: The government has set minimum prices for ethanol made from different raw materials, providing price stability and encouraging production. For example, ethanol made from C Heavy Molasses is priced at Rs. 45.66, while that made from B Heavy Molasses is priced at Rs. 59.08 per liter.

- GST Reduction: The government has reduced the GST (Goods and Services Tax) rates on ethanol production from 18% to 5%, making it more financially viable for producers.

- Ethanol Blended Program: In line with the Industries Act of 1951, the government has facilitated the free movement of ethanol within the country, encouraging its use in various sectors.

- Bank Loan Moratorium: To ease financial burdens, the government has offered a moratorium on bank loans for ethanol production plants.

- Interest Subvention Scheme: The government provides interest subsidies on loans, reducing the cost of borrowing for ethanol producers.

- Subsidies and Schemes: Various subsidies and schemes are available to support ethanol production, making it an attractive business proposition.

Advantages of Ethanol Fuel Production

Embracing ethanol fuel production offers several compelling advantages:

- Environmental Friendliness: Ethanol is a cost-effective and environmentally friendly alternative to traditional fuels. It produces significantly fewer carbon monoxide emissions compared to petrol, contributing to cleaner air and mitigating climate change concerns.

- Reduced Carbon Dioxide Emissions: Ethanol-fueled vehicles emit less carbon dioxide, making them a sustainable choice for environmentally conscious consumers.

- Support for Farmers: Ethanol production relies on crops like sugarcane and grains, providing a steady income for farmers and creating domestic job opportunities.

- Energy Independence: Producing ethanol domestically reduces dependency on foreign oil, enhancing energy security.

- Promotion of Biofuels: Ethanol, as a biofuel, is derived from plant sources like sugarcane, grain, and corn. India’s tropical climate fosters the growth of these crops, making biofuels easily accessible and promoting energy sustainability.

Documentation Required for Ethanol Production

Starting an ethanol production unit involves navigating a bureaucratic maze, with various documents and licenses required:

- Declaration by the EIA Consultant & its Authorization: Environmental Impact Assessment (EIA) documentation is essential to ensure that the ethanol production plant adheres to environmental standards.

- Land Documents: Proof of land ownership, along with the Diversion Order for Industrial Use, is necessary to establish the plant.

- Memorandum & Articles of Association: These legal documents outline the structure and purpose of the company.

- Letter of Intent from Oil Marketing Companies: Securing a commitment from oil marketing companies is crucial for the sale and distribution of ethanol.

- Surface Water Application: This application, submitted to the Chhattisgarh Water Resources Department or relevant authority, ensures access to water resources.

- Steam, Water/Condensate, Fuel & Power Balances: Detailed plans for water and power management are essential to demonstrate operational efficiency.

- Plant Layout: A well-designed plant layout is crucial for the efficient and safe operation of the facility.

Certifications and Licenses

Several certifications and licenses are required to initiate ethanol production:

- State Excise License for Ethanol Production: Obtaining this license is vital for the legal production of ethanol.

- Certificate of Incorporation & Business Commencement Certificate: These documents establish the legality and operational status of the business.

- Fire NOC: A No Objection Certificate (NOC) for fire safety is mandatory to ensure a safe working environment.

- CPCB Permission: Permission from the Central Pollution Control Board (CPCB) is essential for the lawful operation of the ethanol production plant.

- NOC from Local Bodies: Local authorities, including district and village bodies, must issue an NOC for the production plant’s establishment.

- IEM Licenses for Sugar, Cogen & Ethanol: Industrial Entrepreneur Memorandum (IEM) licenses are required to demonstrate compliance with industrial regulations.

- Water Lifting Permission: Permission from nearby water sources, such as the Delhi Jal Board, is necessary to secure access to water for the production process.

- State Electricity Board Permission: Permission from the State Electricity Board ensures a reliable electricity supply to the plant.

- PESO (Petroleum and Explosives Safety Organization): Compliance with PESO regulations is crucial to guarantee safety in the production and storage of ethanol.

Is the Ethanol Production Plant Business Profitable in India?

India has seen substantial growth in ethanol production, with the market demand for ethanol reaching approximately 3,250 million liters in 2021. Predictions indicate that the market could surge to 5,412.06 million liters by 2030. As the demand for ethanol rises, so too does the potential for profitable ventures in this market.

The expansion is expected to be particularly aggressive by 2030, with growth spanning various segments, including additives, beverages, food, and more. Consequently, the ethanol market is poised for significant growth and represents a promising investment opportunity.

Cost of Establishing an Ethanol Production Plant

The cost of setting up an ethanol production plant can vary significantly depending on factors such as capacity and equipment. For instance, an Automatic Ethanol Plant with a capacity of 100 KLPD can cost approximately Rs.120 crores. However, it’s important to note that the actual cost may vary based on individual project specifications and the choice of manufacturers.

Government Guidelines and Support for Ethanol Production in India

The Indian government has been actively promoting ethanol production to meet its ambitious goals for ethanol blending with petrol. On World Environment Day, June 5, 2021, Prime Minister Shri Narendra Modi released the report of an expert committee outlining a roadmap for ethanol blending in India by 2025.

The central government has set a target of blending 20% ethanol with petrol by 2025. In addition to this, state governments, such as Haryana, have also taken steps to boost ethanol production. Haryana’s government has encouraged industries to utilize agricultural stubble for ethanol production and plans to ramp up production in collaboration with sugar mills. Furthermore, the government of India has taken measures to promote domestic ethanol production, including the ban on imported blended ethanol.

Conclusion: Navigating the Path to Ethanol Production

In this comprehensive guide, we have explored the intricacies of starting an ethanol production plant in India, from the essential infrastructure and machinery to the critical raw materials and the intricacies of the production process itself. We’ve also delved into the substantial support provided by the government, including favorable pricing, reduced taxes, and various subsidies and schemes.

Ethanol production not only represents a profitable business opportunity but also aligns with the imperative of reducing pollution, promoting cleaner air, and safeguarding the health of the nation. By understanding the government’s vision for ethanol blending, entrepreneurs and investors can play a pivotal role in India’s journey towards sustainability and energy independence.

As you embark on your ethanol production venture, it is imperative to keep in mind the numerous certifications, licenses, and regulations that govern this industry. Adherence to these requirements is essential for a smooth and legally compliant operation.

NIRMAN ENGINEERS ASSOCIATES, a reliable partner in navigating the complexities of starting an ethanol production unit, can assist you in obtaining the necessary licenses and guide you through the entire process. For more information and support related to ethanol production, please visit our website at NIRMAN ENGINEERS ASSOCIATES.

Remember that this guide serves as a valuable informational resource, but it does not constitute legal advice. The opinions expressed herein are those of the author and have not been evaluated by NIRMAN ENGINEERS ASSOCIATES for accuracy, completeness, or changes in the law.

|

||||||||||||||||||||||||||||